Built to Last!

“Teamwork makes the dream work,” as the saying goes. In stalwart Far-North industries like manufacturing, the dream of a diverse, competitive future workforce is wide awake thanks to a tireless team of employers, institutions, and instructors.

“Teamwork makes the dream work,” as the saying goes. In stalwart Far-North industries like manufacturing, the dream of a diverse, competitive future workforce is wide awake thanks to a tireless team of employers, institutions, and instructors.

For employers in the Northern California manufacturing sector, the fate of the future depends on the effective deployment of career education. That’s why two Redding schools – Shasta College and Shasta High School – are teaming up to narrow the looming skills gap and create a dream scenario for the regional manufacturing workforce.

“It’s wonderful to work with a school like Shasta High that is actively looking to partner with higher education and provide a pathway for student success,” says Rick Osbrink, Industrial Technology instructor at Shasta College.

The collaboration couldn’t come at a more opportune time. The growing deficit between industry demand and supply of qualified workers could leave more than two million positions unfilled nationwide by 2030, according to a study by Deloitte and the Manufacturing Institute.

The Shasta High-Shasta College team-up promotes new dual enrollment opportunities for students in manufacturing pathways. The courses aim to support a seamless transition from high school coursework into college-level curriculum, all the while developing students’ career-ready skills in advanced manufacturing.

“We just rolled out our CAD program here at the college and are in the process of working through the dual enrolling development with Shasta High,” says Osbrink. “On the manufacturing side, we have dual enrolled one of our electronics courses, INDE 38.”

For Shasta High School Advanced Manufacturing instructor Bret Barnes, the upcoming CAD dual enrollment program is a game-changer. Back when he started teaching the Computer Aided Design courses, the class hosted 12 students. Now, he’s instructing 56 in both of his course slots combined.

“It’s all about getting the kids industry-certified in different CAD platforms,” explains Barnes. “Everybody from freshman to senior can get industry-certified and they get a real-life piece of paper that allows them to be highly employable once they leave here.”

The Robotics and Advanced Manufacturing program at Shasta High School is powered by sponsorships from heavy hitters like Google, the U.S. Air Force, and Sierra Pacific Industries. Additionally, says Industrial Robotics instructor at Shasta High School Brian Grigsby, the high school program is working on a project with NASA, wherein both robotics and advanced manufacturing students are flexing their impressive skills.

The Robotics and Advanced Manufacturing program at Shasta High School is powered by sponsorships from heavy hitters like Google, the U.S. Air Force, and Sierra Pacific Industries. Additionally, says Industrial Robotics instructor at Shasta High School Brian Grigsby, the high school program is working on a project with NASA, wherein both robotics and advanced manufacturing students are flexing their impressive skills.

“The kids are designing a space mission that relies on a radioisotope power source to be able to drive the deep space mission,” Grigsby says about the initiative, which seamlessly connects Shasta’s robotics and manufacturing programs. “Then, Bret’s CAD kids will actually do the CAD modeling of the mission.

“We will show NASA engineers and scientists what we’ve built with augmented reality — a virtual reality version of what they came up with.”

As for curriculum, Shasta High School is affording students a strong introduction into Shasta College’s industrial manufacturing pathways. The courses cover industry basics from CNC machining and CAD drafting to industrial robotics courses, even touching on space science engineering. Or, as Barnes puts it: “everything from tool safety to how to use a tape measure.”

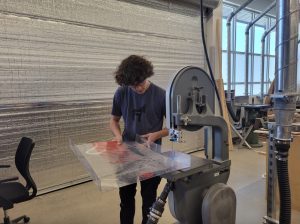

Students at the high school get a solid foundation in manufacturing and engineering, digging deep into the processes and experiencing hands-on learning. Students become familiar with industry-standard techniques and programs like 3D printing, SolidWorks, Fusion 360, AutoCAD, HoloLens, CNC, laser engraving and more.

“We really rely on our industry partners, as well as the connections we have to universities and colleges, and our local community college, to see what [students] truly need,” says Barnes.

The skillsets students learn from the Robotics and Advanced Manufacturing program at Shasta High School are helping them set the stage for career success. Not only do prospects leave the high school program with certifications leading directly into the workforce, Osbrink notes that students who move forward into a college level program can raise their ceiling even higher.

“When students come into our program from schools like Shasta High with a good base knowledge of skills, it allows us to elevate our curriculum to better prepare them for a good career in industry,” says the instructor.

Thanks to Strong Workforce Funding, faculty at the Redding-based schools are giving students the real-world experience, while learning from the safety of a classroom. Shasta High School unveiled new, state-of-the-art CTE facilities last year. Meanwhile, Shasta College was upgrading its welding and manufacturing lab with new, industry-standard equipment. With the recent additions, students are garnering comprehensive, hands-on experience in manufacturing as early as ninth grade.

“Strong Workforce has given us the opportunity to expand our capabilities by allowing us to purchase new equipment, enabling us to stay up-to-date with industry standards,” explains Osbrink.

“The facilities were built using bond money, but our programs and their expansion have been funded through Strong Workforce Program grants,” adds Grigsby, emphasizing the importance of the state-level funding source. “SWP grants helped us to purchase a lot of the larger equipment that we wouldn’t be able to purchase otherwise.”

While the foundation at Shasta High School provides students with a clear pathway to college, their capabilities after graduation are unlimited. Between college, university, or the workforce, the idea is to give students the tools they need to achieve their unique goals independently.

“We’re trying to throw as many opportunities as we can at these students so that they walk out of here with a good portfolio of information that can either be used to try to get a job, or a certification at the university level,” explains the Shasta High School Robotics instructor. “We really try to cover our bases.”

Barnes agrees: “We’re just prepping kids to succeed in whatever they do, plus excite them about the opportunities that are out there in robotics and manufacturing.”

The innovative high school program is already serving as something of a blueprint for other regional manufacturing programs under development. Neighboring Simpson University, for one, is just starting to develop an engineering program of its own, with an eye on Shasta’s success.

The innovative high school program is already serving as something of a blueprint for other regional manufacturing programs under development. Neighboring Simpson University, for one, is just starting to develop an engineering program of its own, with an eye on Shasta’s success.

“They come to us more for guidance because they’re just starting out,” states Barnes. “They come here for advice more than anything else.”

As demand for manufacturing professionals continues to grow, students entering the industry are set for success. CNC machinists’ salaries start at an average of $48,000 in California, with earnings potentially spiking up to $78,000 with experience. Meanwhile, industrial engineers earn an average salary of nearly $101,000.

Salaries are trending up throughout the industry, with positions for CAD drafters and designers forecasted to grow 13 percent statewide between 2020 and 2030. CNC programmers remain in high demand across the state, looking at a projected growth of 26 percent within the next decade.

As the surging manufacturing industry continues to call for help, strong partnerships within the regional manufacturing community are answering.

“We are working closely … to align our programs and develop a pipeline to the college,” Osbrink says proudly.

For the high school instructors, the feeling is mutual.

“The partnership with Shasta College has been incredible,” reflects Barnes. “I don’t think that we would be driving full steam ahead without the support they have given us over the years.

“We’ve gotten to know them, we’ve got a great relationship with them, so we’re excited about what’s been happening and what we continue to do.”

Learn more about Shasta High School Robotics and Advanced Manufacturing by visiting www.shsram.com.

Sources:

Creating Pathways for Tomorrow’s Workforce Today: Beyond Reskilling in Manufacturing:

ONET: California Wages for Machinists: https://www.onetonline.org/link/localwages/51-4041.00?st=CA

ONET: California Wages for Industrial Engineers: https://www.onetonline.org/link/localwages/17-2112.00?st=CA

ONET: California Employment Trends, Architectural and Civil Drafters: https://www.onetonline.org/link/localtrends/17-3011.00?st=CA

ONET: California Employment Trends, Computer Numerically Controlled Tool Programmers: https://www.onetonline.org/link/localtrends/51-9162.00?st=CA

January 2023